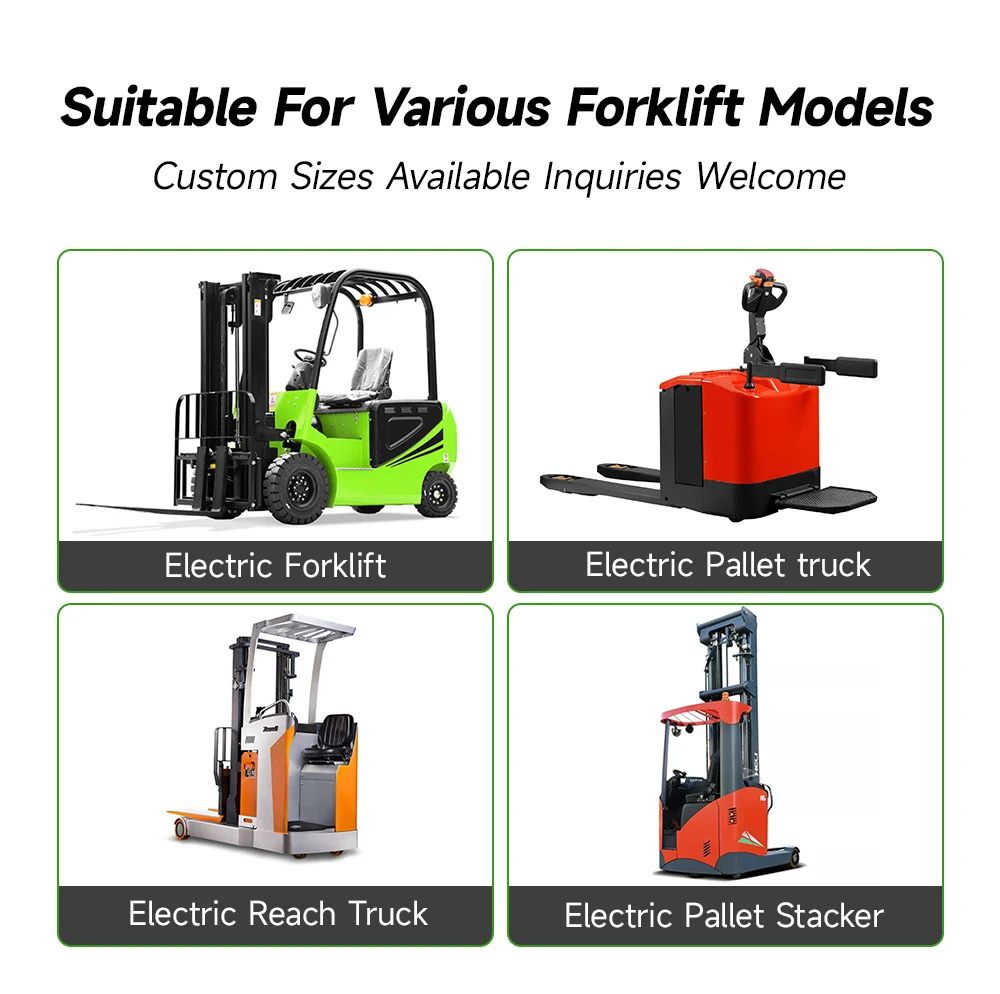

The 80V 560ah Forklift lithium battery is a powerful and durable solution for demanding forklift and material handling applications. Using safe and efficient LiFePO4 cells, it ensures deep cycle, high performance, and reliable operation. Perfect for OEM, ODM, and wholesale buyers, it supports easy installation and delivers strong discharge capability for various forklift models.

Forklift Lithium Battery Feature: