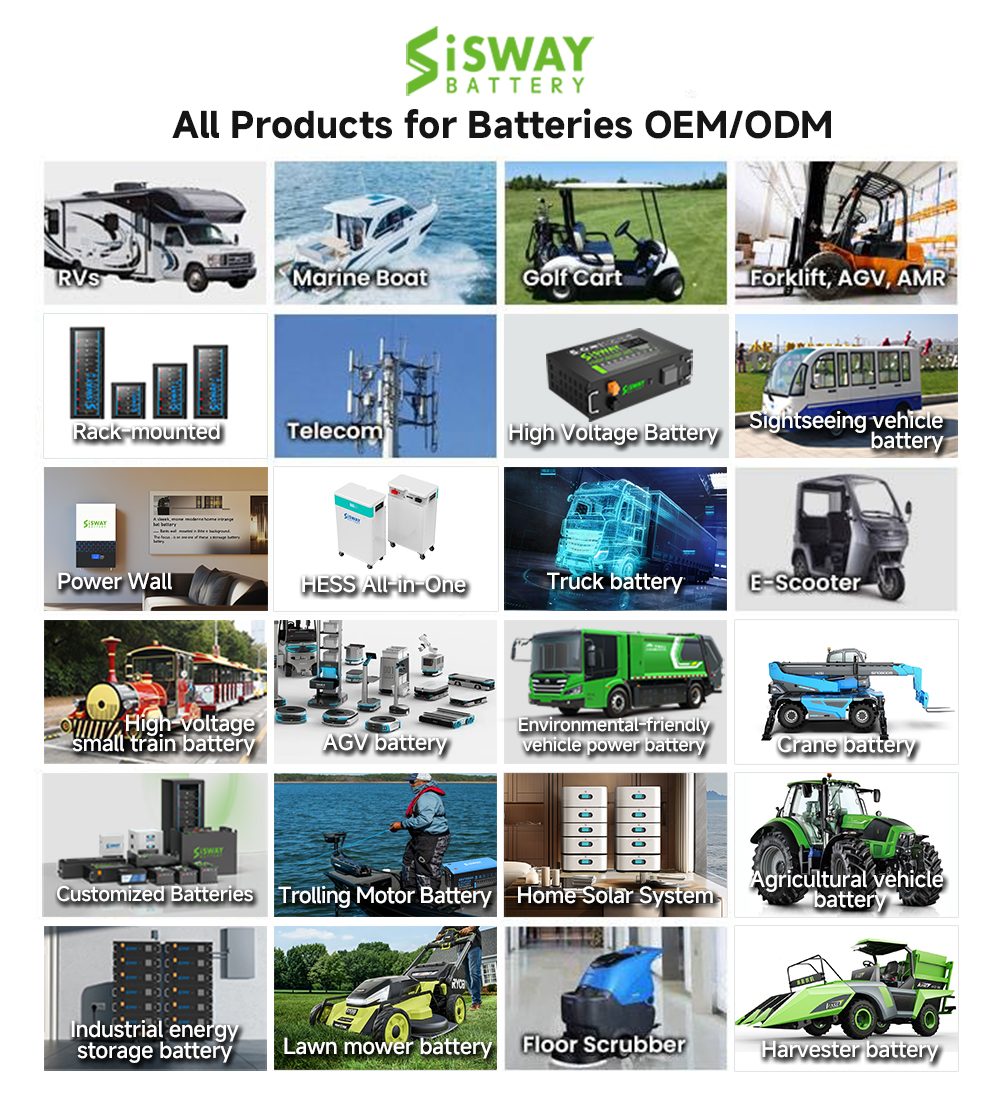

OEM Lithium Battery Services

Over 10 Years of OEM/ODM Experience

Sisway's Commitment to Superior Lithium Battery Quality

With over 10 years of experience, Sisway has earned a reputation as a reliable and innovative custom battery pack manufacturer, offering complete engineering support from initial concept to final production.

Headquartered in Shenzhen, with advanced manufacturing facilities in China, we are equipped to deliver high-quality solutions at scale.

At Sisway, we specialize in the custom design and production of energy storage and industrial battery packs, tailored specifically for OEM clients across a wide range of industries. Our designs are optimized for both performance and manufacturability, with a strong focus on cost-efficiency.

Through our partnership with EVE, we integrate advanced EVE lithium cells reflecting our commitment to quality with long-lasting energy solutions and ensuring unmatched safety and performance.

Backed by proven technical expertise, Sisway proudly offers an industry-leading warranty on our workmanship—ensuring long-term reliability and peace of mind for our partners.

Best-in-Class OEM Lithium Batteries – 2025 Edition

Step-by-Step OEM Lithium Battery Development Process

We connect with global clients through our expert engineers and dedicated sales representatives.

1. Inquiry

Our experienced sales representatives will carefully review the submitted documents to evaluate your project requirements and gather all relevant details.

2. Evaluation

Once we have the necessary information, our engineering team will assess your needs and develop the most suitable battery solution tailored to your application.

3. Specification Verification

The proposed solution will be reviewed internally and shared with you via our sales team for verification and approval.

4. Quotation

After you confirm the proposed specifications, we’ll provide a formal quotation outlining the estimated cost and any associated service fees.

5. Sample Production

To ensure satisfaction, we will produce and deliver sample batteries for your evaluation prior to moving forward with mass production.

6. Price Verification

Following your approval of the sample’s performance and final specifications, we will send a formal pricing document for your final confirmation.

7. Production Schedule

Upon receipt of payment, your sales representative will provide a detailed production schedule and estimated delivery time.

8. Shipment

Finished batteries will be securely shipped to your specified location, ready for integration into your system.

Q: What are the specifications of OEM battery packs used in different vehicles?

A: OEM battery pack specifications refer to the key characteristics of battery systems used by various vehicle manufacturers. These include essential details such as battery capacity, voltage, energy density, and more—each playing a vital role in determining a vehicle’s range, performance, and efficiency.

Battery Capacity & Voltage: Capacity (measured in kWh) indicates how much energy the battery can store, while voltage (measured in volts) determines the power output. Both factors directly impact the performance and driving range of electric vehicles.

Energy Density: This measures how much energy is stored per unit of volume or weight. Higher energy density leads to longer driving ranges and better space efficiency within the vehicle.

Additional Specifications: OEM battery packs may also include information about charging speed, cycle life, safety mechanisms, and warranty coverage. These features help users make informed choices when selecting a battery pack for specific EV models or applications.

Q: What are the different cell types and capacities used in OEM battery packs?

A: OEM battery packs typically use three main types of battery cells: cylindrical cells, prismatic cells, and pouch cells. Each cell type has its own advantages and is chosen based on the specific needs of the vehicle or application. The capacity of these cells can vary depending on the battery pack design, offering different performance capabilities and driving ranges.

Cylindrical Cells: These round cells are renowned for their high energy density and mechanical stability, making them ideal for high-performance applications. Their consistent shape also makes them well-suited for automated manufacturing processes.

Prismatic Cells: Featuring a rectangular, prismatic shape, these cells are typically encased in aluminum or steel. Their design allows for easy stacking and efficient packaging, making them a popular choice for certain OEM battery packs where space optimization is crucial.

Pouch Cells: Pouch cells, also known as flexible or laminated cells, have a flat and lightweight structure. They provide design flexibility, cost-efficiency, and are commonly used when space and weight are key factors, such as in compact or lightweight electric vehicle designs.

Q:What Are Hot OEM Battery Packs and Their Features?

A: Hot OEM battery packs are high-performance energy storage systems used in electric vehicles. These packs are engineered to deliver superior power, efficiency, and reliability, incorporating advanced features that enhance vehicle performance and user convenience.

High Performance: Hot OEM battery packs are designed to provide high energy density and power output, enabling electric vehicles to achieve impressive acceleration and overall performance. This contributes to a more dynamic and efficient driving experience.

Fast Charging Capabilities: One of the standout features of hot OEM battery packs is their fast-charging capability. With quicker charging times, these packs reduce downtime, making electric vehicles more practical and user-friendly for everyday use.

Advanced Thermal Management: Equipped with cutting-edge thermal management systems, hot OEM battery packs regulate their operating temperatures, ensuring that they stay within optimal ranges. This improves both efficiency and battery lifespan, while maintaining reliable performance across a variety of driving conditions.

Battery Management System (BMS) Integration: These battery packs are seamlessly integrated with sophisticated Battery Management Systems (BMS) that monitor key parameters like voltage, temperature, and state of charge. The BMS ensures the safe operation of the battery and optimizes its overall performance and longevity.

Q: What different types of battery packs are available?

A: Battery packs can be classified into two main categories: primary (non-rechargeable) and secondary (rechargeable). Understanding the differences between these types is essential for selecting the right battery pack for your specific needs.

Primary (Non-Rechargeable) Batteries: These batteries are designed for single-use applications and cannot be recharged once their energy is depleted. While they offer a reliable power source for many devices, they are disposable. Common examples include alkaline and zinc-carbon batteries.

Secondary (Rechargeable) Batteries: These batteries are designed to be recharged and reused multiple times. They are more cost-effective and environmentally friendly as they can be recharged through various methods, such as using electrical outlets or renewable energy sources like solar power. Examples include lithium-ion, nickel-metal hydride (NiMH), and lead-acid batteries.

Battery Chemistry: Battery packs are also categorized based on their chemistry, which influences their performance, lifespan, and applications. Common chemistries include lithium-ion, lithium-polymer, nickel-cadmium (NiCd), and nickel-metal hydride (NiMH). Each chemistry has unique advantages and limitations, making them suitable for different uses, from consumer electronics to electric vehicles.